Industrial Grade Synthetic Lubricants in Texas, Arkansas, Oklahoma and Louisiana

Industrial Grade Lubricants in Texas, Arkansas, Louisiana & Oklahoma

At Red River Oil Company, we specialize in the delivery of fuel, oil, and industrial lubricants throughout Texas, Arkansas, Oklahoma, and Louisiana. For decades, we have been the trusted supplier and distributor to wholesale and retail customers, commercial and industrial customers, and agricultural sites. We are a locally owned and operated company that values integrity, honesty, and transparency. We only sell the highest quality synthetic lubricants and industrial oils and lubricants to our customers. Call us to ask about our services or inquire about pricing for our products and equipment.

What Is Synthetic Lubricant?

Synthetic industrial lubricant is a chemically synthesized fluid used in industrial applications. This type of lubricant is made from chemically modified petroleum components or other raw materials. Each manufacturer may use a different manufacturing process and different additives.

What Are the Benefits of Industrial Lubrication?

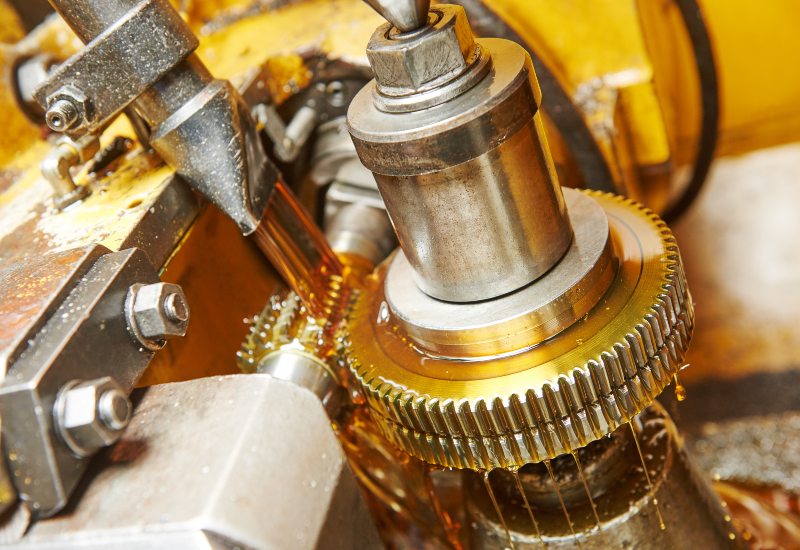

Industrial oils and lubricants are used to lubricate moving parts and surfaces of industrial equipment, machinery, and vehicles. Synthetic industrial oils and lubricants offer many benefits, including:

- Reduced friction, which reduces the wear and tear on your equipment and extends its lifespan.

- Less heat, which prevents overheating and degradation.

- Improved performance, safety, and efficiency of parts, equipment, machinery, and vehicles.

- More eco-friendly operation, as emissions are reduced.

- Less noise and vibration.

- Lower risk of downtime or delays caused by breakdowns and failure of equipment.

- Reduced labor costs as equipment will function more effectively and efficiently.

Main Types of Industrial Lubricants

Our experts can help you determine which type of industrial lubricant is right for your needs. We want to help you choose a lubricant that improves the performance, efficiency, safety, and lifespan of your equipment. The most common types of industrial lubricants are synthetic industrial oils, mineral oils, and grease:

- Synthetic Industrial Oils—Synthetic oils are higher-performing and can withstand extreme temperatures without degrading or breaking down. This means that they are ideal for use in high-temperature environments, such as heavy equipment and machinery, engines, and large equipment.

- Mineral Oils—Mineral oil is a natural oil that is low-cost and easy to use. However, it is less effective in hot environments than synthetic lubricants.

- Grease – Grease is often a heavy oil mixed with a thickener, so that the grease doesn’t dissipate when machines are in operation.

Factors to Consider When Choosing Industrial Oils & Lubricants

We will help you consider some key factors when choosing the ideal industrial lubricant for your industry and purpose. These are the most important factors to consider:

- What Will the Lubricant Do? The lubricant you choose will depend on whether you are primarily using it to control friction, wear and tear, corrosion, contamination, or temperature.

- What Ingredients Are In the Lubricant? You should choose a lubricant with additives that improve its performance for its intended purpose.

- Weight, Viscosity, and Consistency – A higher viscosity offers more flow resistance. The fluid’s weight also accounts for how viscous it is and how easily it will flow at certain temperatures. The lubricant’s consistency affects how hard and soft it is and how it will perform in certain environments.

- How Easy Is It to Use? Not all lubricants are used in the same way. You want to choose one specifically tailored to where and how you will apply it.

- Lifespan – Each type of lubricant has a specific lifespan and must be replaced when it expires.

- Cost – Buying low-cost lubricant often means it is also low quality. For expensive, complex equipment, you need to invest in high-quality industrial lubricants that will perform well and last as long as possible.

Common Mistakes In Choosing Lubricants

We can also help you avoid common mistakes when choosing your lubricants. You can avoid safety issues, performance issues, and dangerous mistakes by avoiding these mistakes:

- Allowing fluid to become contaminated by dust, dirt, or water.

- Choosing the wrong type of lubricant.

- Choosing incompatible lubricants.

- Applying lubricant incorrectly.

- Storing and handling lubricant improperly.

- Using lubricant beyond its stated lifespan.

- Using lubricant outside of its recommended purpose.

How to Properly Store Industrial Synthetic Lubricants

The proper storage of industrial synthetic lubricant will preserve its performance, efficiency, efficacy, and lifespan. Follow these tips for storing industrial lubricants:

- Store lubricants horizontally in tightly sealed containers made from steel, stainless steel, or high-density polyethylene.

- Store lubricants in a cool, dry, clean place.

- Maintain a temperature between 50-80 degrees Fahrenheit.

- Ensure proper ventilation.

- Keep storage containers wavy from direct sunlight, heat, steam, and humidity.

Why Choose Red River Oil Company

At Red River Oil Company, we are proud to be the leading industrial lubricant distributor in our four-state region. We provide quality fuel, petroleum products, industrial oils and lubricants, and specialty products to the agricultural, transportation, mining, automotive, manufacturing, and aviation industries.

Contact Our Industrial Lubricants Suppliers Today

Call or contact us online to learn more about the supply, delivery, and distribution of industrial lubricants in Arkansas, Texas, Oklahoma, and Louisiana. We offer highly personalized services and cost-effective solutions that will help you improve the safety and efficiency of your work functions.