Gear Lube in Texas, Arkansas, Oklahoma and Louisiana

Premium Gear Lubricants in Texas, Arkansas, Louisiana, & Oklahoma

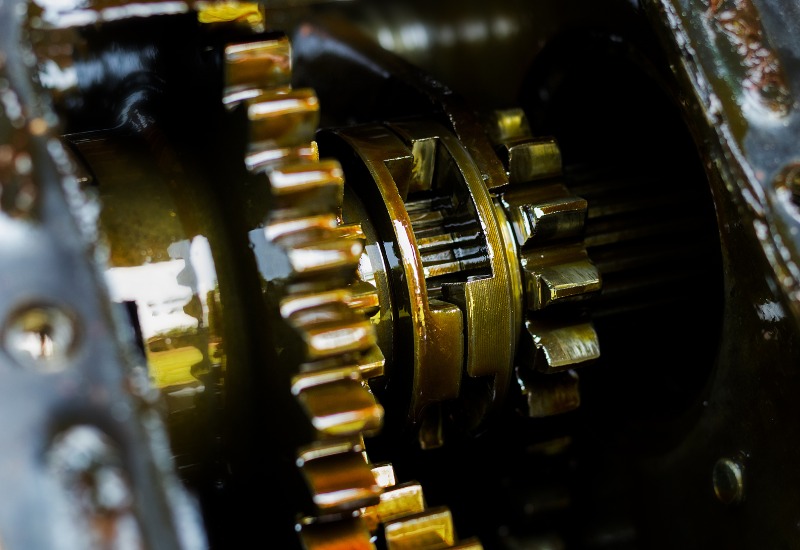

Gear lube is a necessary lubricant for vehicles, machinery, and equipment. It can enhance the performance and extend the lifespan of gears. At Red River Oil Co., we specialize in lubrication products for a wide range of industries, including automotive, farming and agricultural, transportation, and construction. Our gear lube services are available throughout Texas, Arkansas, Louisiana, and Oklahoma. We guarantee quality gear lube that can protect your gears and other components from wear and tear, damage, and the need for costly repairs or replacements.

What Is Gear Lube?

Gear lube is a specialized, high-quality oil used to lubricate the gears and other components of machinery, equipment, and vehicles.

Types of Gear Lube

We offer different types of gear lube depending on the equipment being lubricated and the industrial applications of the equipment:

- Manual Transmission Fluid – Manual transmission fluid is used in vehicles with a manual gear system.

- Automatic Transmission Fluid – Automatic transmission fluid is used in vehicles with an automatic gear shift.

- Differential Gear Oil – Differential gear oil is designed for gears that cause wheels to move at different speeds on rough terrain.

- Transfer Case Fluid – Transfer case fluid lubricates the gears, chains, and other components inside a vehicle’s transfer case. or gearbox.

- R&O Gear Lubricants – R&O, or rust and oxidation-inhibited gear lubricants, are best for gears that operate at high speeds but with low loads and no shock loading. They don’t contain antiscuff additives or lubricity agents.

- Antiscuff Gear Lubricants – Antiscuff gear lubricants are ideal for high-pressure applications and have enhanced performance capabilities. They contain additives that enhance strength and load-carrying ability.

- Compounded Gear Lubricants – Compounded gear lubricants are a mix of synthetic fatty acids and oil. They are typically used for worm gear applications.

Applications of Gear Lube

Gear lube is necessary in a wide range of industrial applications. Our gear lube services can be used for:

- Automotive – Gear oil can be used in manual and automatic transmissions, transfer cases, transaxles, and differentials for cars, trucks, and other vehicles.

- Industrial – Our gear lube services can lubricate air compressors, blowers, cranes, hydraulics, turbines, vacuum pumps, bearings, and gearboxes.

- Agricultural and Farming – Gear oil can maintain and lubricate agricultural and farming equipment, machinery, and vehicles.

- Mining – Gear lube is ideal for open and semi-enclosed gears on mining shovels, excavation equipment, and draglines.

- Transportation and Construction – Our gear oil services are ideal for maintaining and lubricating vehicles and construction equipment, including excavators, back hoes, shovels, mills, draglines, and more.

- Manufacturing – Gear lube can lubricate the gears of machinery and equipment.

Benefits of Using Gear Lube

Gear oil ensures a vehicle’s transmission runs smoothly and protects internal components of vehicles, equipment, and machinery from wear and tear, damage, corrosion, scouring, scuffing, heat damage, and pitting. The biggest benefits of using gear lube are:

- Enhanced performance of vehicles, equipment, and machinery.

- Reduced wear and tear and degradation.

- Lower risk of damage to components.

- Extended lifespan of vehicles and components.

- Reduced need for maintenance and repairs.

- More cost effective.

- Guarantees productivity and efficiency.

- Reduced labor needs and costs.

How to Choose the Right Gear Lube

When choosing the right gear lube, you should consider the application of the gear fluid, its viscosity, and whether you want to use synthetic or conventional gear lube. We offer a wide range of oils, lubricants, and specialty products. Our expert technicians can help you make the right choice:

- Proper Type of Gear Lube for Your Application – You will first need to choose the right type of gear lube for the equipment, vehicle, or machinery you are lubricating.

- Viscosity of the Gear Oil – Gear oils have different viscosities, measured in grades. The viscosity is measured by two numbers separated by a W, which stands for winter. The first number indicates the viscosity in cold weather, and the second number is the oil’s viscosity in hot weather. The higher the number is, the thicker the oil. A thicker oil is necessary for high-heat and high-pressure applications.

- Synthetic vs. Traditional Gear Oil – Traditional gear oil is petroleum-based. It is ideal for preventing premature wear and tear, breaking in newer gear teeth, and protecting gears from heavy loads. Synthetic gear oil is a mix of traditional materials and manufactured oil. It is ideal for extreme hot and cold temperatures, dusty and dirty environments, and wet climates.

- Base Oil – In some applications, you will also have to consider the base oil of your gear lube. Most applications call for a high-quality mineral base oil, but you may consider synthetic base oil.

Common Gear Lube Issues & Solutions

Our technicians have decades of knowledge and experience that can help you prevent or overcome gear lube issues in any application. The most common gear lube issues we encounter are:

- Contamination – Gear lubricants can become contaminated with dirt, water, and dust due to poor storage and broken or damaged seals. The oil will be less effective and can damage the gears. We can regularly inspect and test gear oils and seals, and ensure they are in proper condition.

- Mixing Different Types of Lubricants – Mixing different types of lubricants can cause a dangerous chemical reaction or affect the performance of your vehicle, machinery, or equipment. We will ensure you are using the right type of gear oil for your needs and that no different lubricants are mixed.

- Using the Wrong Type of Lubricant – The wrong type of gear lube can cause safety and performance issues and reduce the lifespan of your vehicle, machinery, or equipment and its components. We ensure you use the right lube for your application.

Contact Us for Gear Lube Services

Call us now or contact us online at Red River Oil Co. to learn more about our gear lube services in Ashdown, Texarkana, and Foreman. Our expert technicians will ensure you have the right gear lube oil for your industry and applications. We also carry quality equipment, including gear lube pumps.